Center of Gravity: Have your engine (gravity) power your car for longer

Previous lessons: Density

Things needed for this lesson: raw egg, a ruler and some small coins

Concepts in this lesson: Galileo's theory of gravity, inertia, center of gravity

Time: 30 minutes

Parents: First thing you will do is look at your Pack's website or google some images of past events. Look at the shape of the track you are using. Parents, not engineers, buy these tracks. Almost all of the time, the ramps start off steep and then flatten out at the end. But I have seen online one time when someone had a straight-line ramp - one that just goes in a straight line and never changes angles to the finish line, then this point is irrelevant to this lesson as all cars will accelerate the same. This lesson only matters when the ramp curves near the bottom.

"Let's say you have two ball that are the exactly same size and outer covering material. One weighs 5 ounces and one weighs twice as much - 10 ounces. Let say you drop those two ball at exactly the same time off a building. Which falls faster?

With the same air resistance or no air resistance, they fall at the same time.

Here's a great Mythbusters clip to watch to reinforce this physics lesson:

http://www.youtube.com/watch?v=7eTw35ZD1Ig

Inertia

If gravity is pulling harder on things that have more mass, why do things fall at the same speed that have different masses? The answer is

inertia. Inertia is another force. It is force that keeps something at the same speed. Think of riding a bike. It takes more energy to start pedalling because the bike and you on it have mass and that mass is not moving yet. Inertia is a force keeping you at your current speed, which is zero. Once you get the bike moving, it takes a lot less effort to keep moving. If you stop pedalling, you will keep coasting. And now it takes effort to stop. Bike brakes are pretty good at stopping you. But imagine how much effort you would need if you didn't have brakes and could only put your feet down to stop. Yikes!

(Take out the raw egg. Do nothing to it)

The egg doesn't want to move, so it takes effort to move it.

(Spin it on a smooth table surface. Tap the top quickly so it comes to a stop. And then watch as the egg then starts spinning again).

The egg white and yolk inside wants to keep spinning. That's inertia.

Inertia works in the opposite way of gravity and is also related to mass. So gravity pulls harder on heavier things. But inertia means that heavier things are harder to get going. Gravity and inertia are both related to mass in the same way*. Gravity still works, but things drop at the same speed.

A big difference: center of gravity

You are probably thinking, "Hey, all our cars are going down the same track. They should all "fall" down the track at the same speed, regardless of weight."

That is totally correct.

We roll our Pinewood Derby cars down ramps. Ramps converts the direct downward pull of gravity into downward AND forward energy. So the car travels a longer distance and goes slower than just dropping them, but all cars should go the same speed if they are dropped at the same time, have the same center of gravity, and have the same resistance from friction.

The very important thing to remember is that things fall at the same speed *IF* they had the same center of gravity and *IF* resistance from friction is the same.

Think of three Pinewood Derby cars of equal weight - 5 ounces - with exactly the same aerodynamics and friction.

One car is heavier in front.

One is heavier in back.

One is balanced.

Which one will go faster?

Answer: one one that is heavy in back

Why?

If you put a one ounce block on a scale and drop both at the same time, what will the scale read?

The answer is zero. The block has mass, but no weight because gravity has converted all of the mass's weight into motion.

If you lower something slower than the speed of falling, some of gravity's force is converted into motion and some of it is converted into weight. A scale and block in an elevator going down will say that the block weighs less than an ounce. A scale and the block on the ground will say one ounce because the scale is not moving and all of the force of gravity is converted into weight.

We design where the five ounces of mass in a Pinewood Derby goes, so that gravity will affect the mass into motion longer than other cars.

When Pinewood Derby cars of equal friction go down a ramp, they will all go the same speed because gravity accelerates them the same. But there is a point where the track is flat. Just before that the steep part reaches the flat part. At that point, the front wheels are on the flat part and the back wheels are still on the downward curve. The front mass has nowhere left to go down, so its mass is converted 100% into weight. In the back, gravity can still convert the mass into motion because there is still downhill ramp for it to move down. So the more mass that is in the back, the longer gravity will pull your car down the ramp. And gravity's speed is not linear (you don't move at the same speed down the track), it is exponential. So a fraction of a second of gravity turning into motion is a lot as that is when the car is at its fastest.

So there is that moment at the bottom of the ramp curve where the cars reach the bottom of the ramp and then move completely onto the flat second. These are 7 inch cars. The commercial aluminum tracks are typically 42-49 feet long in length, where cars are travelling at about 160 inches per second. The whole car will pass that transition point in about 0.05 seconds.

There is something called the center of gravity. It is where half of the weight is on one side and half of the weight of something is on the other. You can do it with a ruler. A ruler with nothing on it will have its center of gravity in the middle. But as you put coins on one side, the center of gravity where you can balance it on one finger moves toward the coins.

You want your center of gravity as far back as possible, but not in front of the back axle.

This means two crucial things for design:

#1. Move your back axles grooves backward to the maximum 5/8".

#2. Do not make your car shorter than 7". The front of the car is leaned against a starting gate. But you want you rear, where all the mass is, as high as possible so it can fall for a longer time period.

Look at the following videos on Youtube. Watch the cars come down the ramps. According to the law of gravity, the cars will "fall" down the ramp at the same speed *if* their aerodynamics and friction are the same. However, we know that aerodynamics and friction are not equal, so some cars are slowed down by more friction. So the first car to the curve (the car with less friction and better aerodynamics) should win, right? Wrong.

Look at the following video and turn down the volume:

http://www.youtube.com/watch?v=tC5qRw7QhLA

The first race has all four cars racing at very similar speeds down the ramp. The two cars in the middle ramp are in a slight lead because they have less friction. But the race changes when they hit the curve at the bottom. At that point, the two outer cars go faster and pass the two inner cars.

The second race is dominated by a single car, so it's not a good example.

The third race at 0.47 seconds into the video is a good example. We see two outer lanes' cars that have less friction than the middle two. They are very close to each other. But watch the outer two when they hit the curve. The one in the far right lane suddenly appears to really pull away at the curve.

The fourth heat at 1:10 is not a clear example as all four cars keep the same place down the ramp and after the curve.

The fifth heat at 1:20 is a good example. Three cars racing, two in the left are very tightly matched down the ramp but the one in the far left lane has the lead, which it then loses at the curve (but still pulls it out).

The sixth heat at 1:30 is also not a good example as there is no change of leads. The last place car probably wasn't helped by having zinc weights glued all along the top rather than clustered as tightly as possible in the back.

The seven race at 2:20 has a non-spec car that wins in a head-to-head, so it is not that much help.

The eight race at 2:52 is a second place bracket run-off. These cars are very very evenly matched down the ramp. It is so close that any observation might be subject to point-of-view and camera quality error. However, my view is that the the car on the far right appears to be slightly less than the other two cars. The longer in the left lane seems to gain a tiny speed advantage in the curve (but then loses it).

The ninth race at 3:07 is pretty close, but again the curve is where the faster car separates. You can see two putty marks in the back of the winning car and only one in the back of the losing one. The winning car appears to have its weight farther back.

The tenth race at 3:20 is my favorite example. Focus on the third and last place cars down the ramp. The car in the second from the left lane is close, but still in last place coming down the ramp because he has more friction that the other cars. At the curve, the two on the right separate like they had an afterburner (they did; it's called gravity). The last place car - despite having more friction - passes the third place car in the course of about three feet.

The 11th race at 5:23 is not a good example.

But in five races, the center of gravity effect at the curve seemed to be a major impact on determining the winner and the eighth race it's debatable, so let's call it a half. So in 5.5/11 races, center of gravity was a noticeable effect. Again, you can see how small the difference is, but how much of a difference it makes in who wins.

The last thing to note is that, if you are using tungsten weights, it is possible to put the weight too far back. Do not have your center of gravity too close to your back axle. With a popsicle stick or a ruler, you can see where you car will balance. If it is next to the axle holes, you will have to move some weight forward. If you put your weight too far back, the car loses stability and will rattle back and forth. This will translate downward speed into side-to-side energy and slow you down.

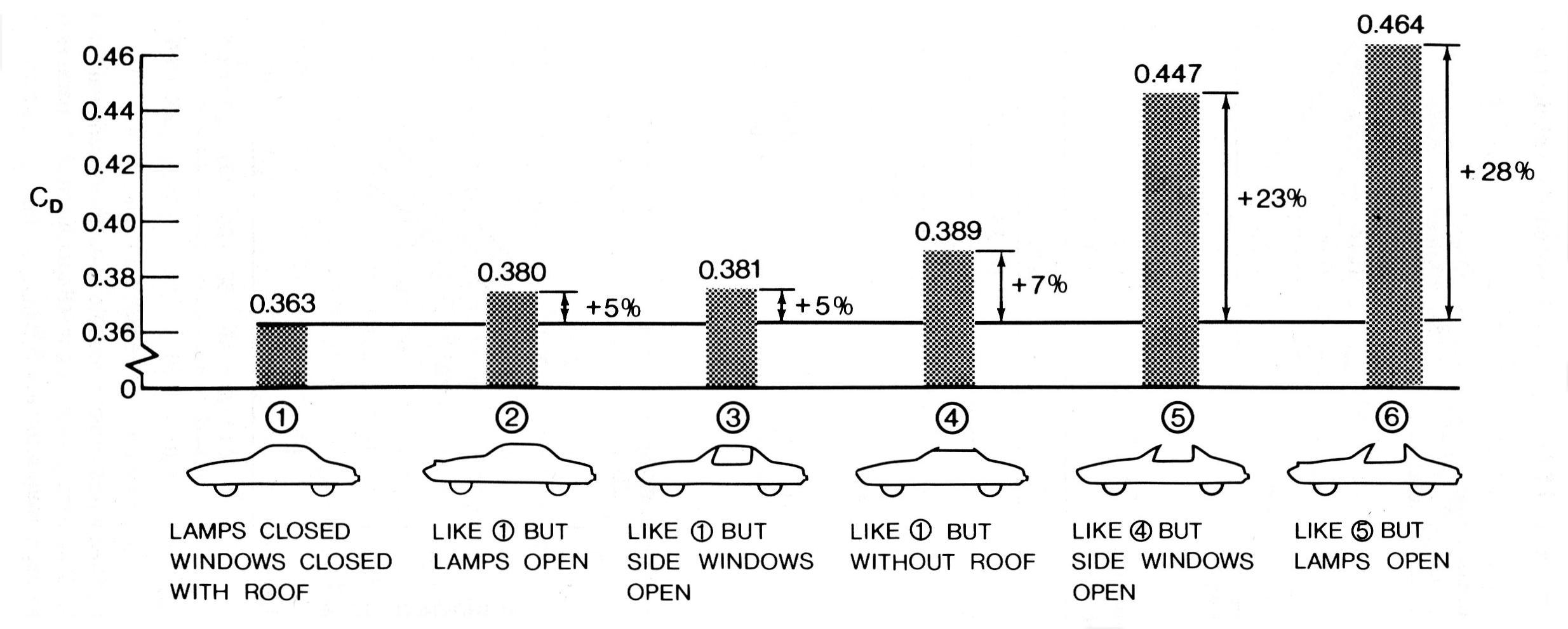

Next up: Aerodynamics